Menu:

Scooter Mods

I decided to buy a couple of the Xiaomi M365 Mi Electric Scooters to use with friends and also ride to work. After I got them, I noticed a few things I wanted to change or fix.

The first change I wanted to make was to add a skid plate to the bottom. On the bottom of each scooter is a plastic cover held in place with button head screws, so if you end up going over something that touches the bottom of the scooter, I'm sure there's a good chance you might shear off the top of some of the screws.

Using my Glowforge laser cutter, I decided to make a skid plate out of Delrin. I copied the shape of the bottom cover with the screw holes. I had to split it into three pieces to fit on the material I had. The image below shows a screenshot from the laser cutter software with the design for one of the parts.

Because the part was so long and thin, the material warped and moved during the first cut, so I added magnets to the next test to keep the material in place. This is shown in the image above.

The image below shows a piece of Delrin after having the first part removed, and the second part cut. You can see how much the material was warping by how much the bottom edge is curved up.

After cutting out all of the parts, I used a countersink bit on each of the screw holes so I could replace the button head screws with flat head screws. The image below shows the scooter after adding the first piece.

The image below shows the finished product with all three pieces attached to create the skid plate.

Another modification I wanted to make was to add a number to each scooter. I wanted to do this mostly so I could tell them apart if the battery levels were different. I removed the part on each scooter that holds the bell onto the handlebar, and put it in my laser cutter. Then I engraved a number 1 and 2 on the parts. One of these is shown below.

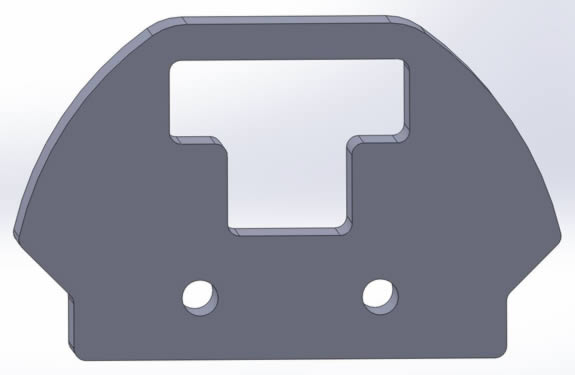

The final change I made was to fix a rattle that seems to be common on these scooters. On one of my scooters, there is a gap in the folding mechanism that causes a rattle when you go over bumps. Other people have solved this with a thin 3D printed part that fits in place to take up the gap. Since I no longer own a 3D printer, I decided to make this part with a thin sheet of Delrin on the laser cutter. The design for this part is shown below.

The part slides over the latch and then a zip tie holds it in place using the two holes. The attached part is shown below.

It will still occasionally make some noise, but this part mostly fixed the issue.

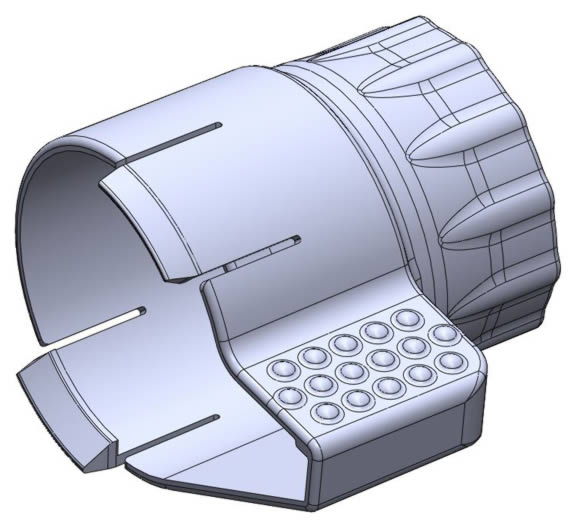

After a few years I bought the newer Ninebot Kickscooter Max G30P. I decided to design a part to extend the throttle a bit so it could be used as a twist throttle instead of just a thumb throttle. A screenshot of one of the first few designs is shown below.

Along with extending the throttle I also added some texture features and snaps to hold it in place.

The first four parts I printed are shown below. The first was a test part to check fit, and then three designs with all of the features as I tweaked things to get it to fit how I wanted.

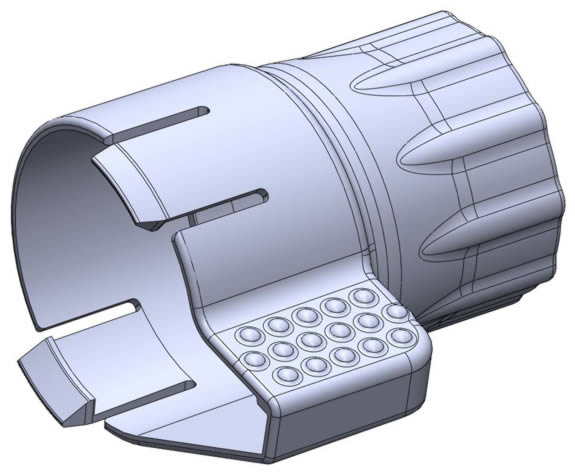

After testing out the final part above I decided to extend the twist feature a bit, as well as make some other changes related to the snap geometry and a few other small details. As I was making different iterations I was also experimenting with different materials and build orientations. The different build orientations were needed to get the surface finish I wanted while also making sure the snaps were strong enough. The final design I ended up with is shown below.

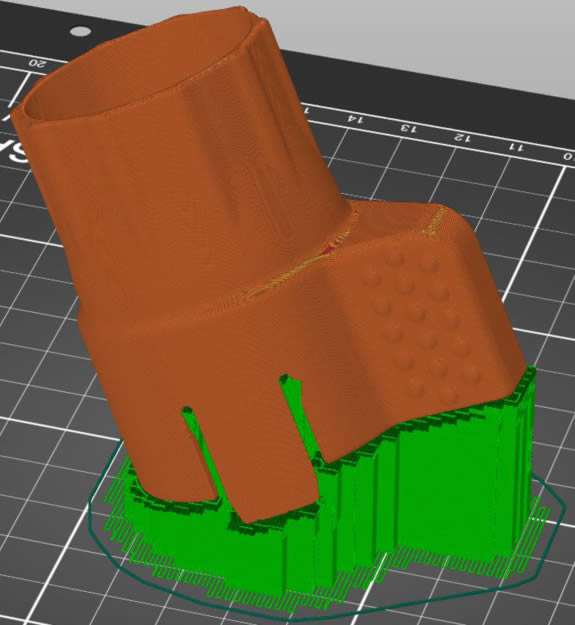

A screenshot of the final design that would be printed on my Prusa i3 MK3S in PETG is shown below. I ended up rotating the part by 13 degrees in X and 25 degrees in Y from the way the STL file was imported to get the finished part I wanted, and printed with 100% infill.

The image below shows the throttle without my part attached (notice the part may scratch up the hand grip).

And the next image shows what it looks like with the part attached.

I ended up printing quite a few parts for this project; most of them are shown below, with two parts made from the final design at the bottom of the image. I ended up testing with PETG, ASA, nylon, and a PC blend. The snap features on the ASA and PC blend parts were a little too brittle. The nylon parts were a little too flexible, and fully removing the support material was almost impossible, so I ended up going with PETG.

This part makes it a little easier to hold the throttle at various positions. The first file below can be used to make this part for the Ninebot Max (it also works with the Xiaomi M365). The second file ending with F40 works on the Ninebot F40 scooter (and I'm assuming with the other F Series models). The grip design on the F40 is different than the other two scooters so I had to redesign the part to fit over it. After using the parts for a while I realized the texture bumps were a little too rough and uncomfortable, so I also created some files with the bumps removed, which I prefer. They are the third and fourth files below.

(Throttle Clip-v9-Large ID .stl)

(Throttle Clip-v9-Large ID-F40 .stl)

(Throttle_Clip-v9-Large_ID-No_Bumps .stl)

(Throttle_Clip-v9-Large_ID-F40-No_Bumps .stl)

Page created: 2018